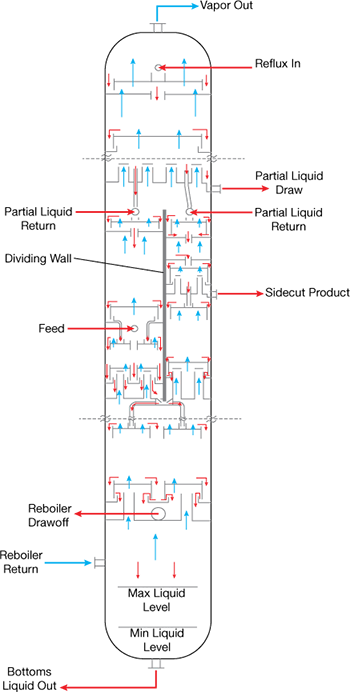

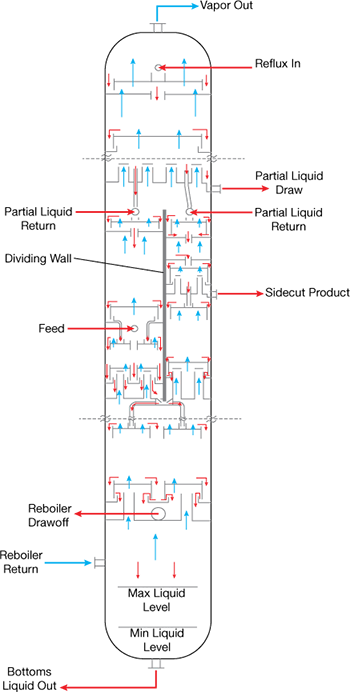

▲ Figure 1. A standard dividing-wall column (DWC) has a wall that separates the column into two sections. The flow of vapor and liquid is shown with blue arrows and red arrows, respectively.

Dividing-wall columns (DWCs) are a type of distillation column that can separate mixtures of several components into three or more high-purity streams (Figure 1). A DWC requires much less energy, capital investment, and plant space than conventional columns in series or parallel configurations. In fact, DWCs can have 20–30% lower capital cost requirements than conventional tower designs (1–5).

Conventional distillation columns are an integral part of the refining and chemical industries. Retrofitting existing columns with a dividing wall to improve separation efficiency is part of a larger push to intensify processes in these industries. Process intensification (PI) targets dramatic improvements in cost and energy efficiencies by rethinking traditional operation schemes. A DWC is one example of an intensified technology.

The concept of DWCs is well established, with much literature focusing on the simulation and control of these columns (1, 6, 7). Several publications have discussed the industrial applications of DWCs in different grassroots and retrofit applications (8, 9).

The technology is quite versatile, and no two DWC applications are exactly the same. Thus, it is difficult to develop a standard protocol for designing these columns. DWCs have been implemented in a variety of applications, such as gas plants, naphtha splitters, and reformate splitters, among others.

This article describes the three basic types of DWCs. An example demonstrates how adding a dividing wall can improve the purity of a side-cut stream without requiring the addition of a second column.

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.